OUR TECHNOLOGY

Innovative Die Casting solutions

Experts in casting the automotive leading alloy

ALUMINIUM DIE CASTING

Aluminium is one of the most important materials for car makers, as well as it is for Zatorcal.

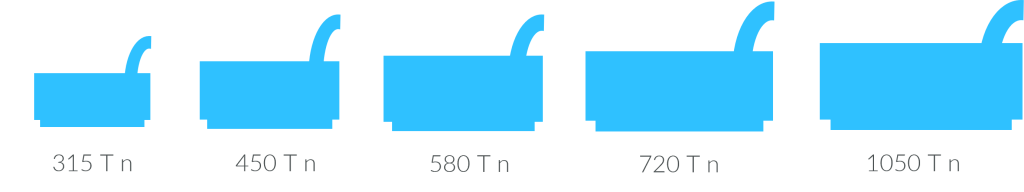

Our company has a wide range of Die Casting machines to make tailor-made solutions depending on our clients necessities.

Aluminium Die Casting cells

Our aluminium solutions guarantee lightness and maximum performance

Wide competence on producing the lightest metal components for the auto industry

MAGNESIUM DIE CASTING

Magnesium is a present and future material due to its technical and weight reducing capacities.

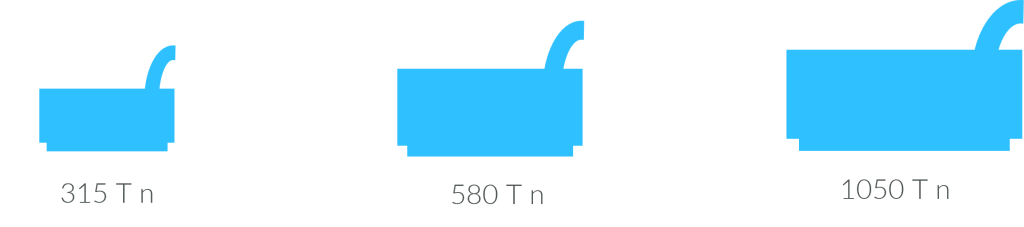

Zatorcal owns capacity and experience in Magnesium Die Casting in order to build lighter and more sustainable cars.

Magnesium Die Casting cells

Wide competence on producing the lightest metal components for the auto industry

All kind of surface finishing solutions

FINISHING PROCESSES

Zatorcal focuses on providing the best quality to our clients through internal capabilities or via partnerships

Internal capabilities

Zatorcal has in-house capacities that let us achieve best finishings for our components.

Specialized suppliers

Zatorcal has a large network of specialized suppliers in surface treatments to the pieces.

These strategic providers can do us painted treatments, machined, sharpened, vibrated, among others.

They are all certified according to auto industry standards.

Complex moulds that guarantee success in serial production

MOULDING DEVELOPMENT

Zatorcal develops high complexity moulds that guarantee sucess in serial production.

In-house engineering

Zatorcal engineering team is focused on industrialization of client’s projects. Our objective is to design components and moulds that guarantee a successful serial production. To do so, we use:

- CAD designing

- CAE simulation

- 3D printer virtualization

Collaboration

Mould development and building together with our reliable suppliers

EMPOWERING THE LEADING TIER 1'S OF THE AUTO INDUSTRY